Conventional RFID systems can identify assets passing through a portal, but once inside a warehouse locating the assets becomes a substantial challenge. Tagging each of the potentially thousands of assets in a typical logistics scenario is cost-prohibitive. But by identifying an asset, associating it with a forklift, and then tracking the forklift, a small number of active tagged forklifts can enable keeping track of a large number of assets. More on how Q-Track developed this innovative concept for real-time location awareness of assets may be found on the Q-Track website.

This system can be employed in situations where pallets are stored and stacked in open areas as well as in racks. Further, there are a number of secondary benefits of tracking forklifts, including:

- Analysis and optimization of forklift utilization

- Proximity detection and collision avoidance (when tracking workers also)

- Monitoring speed of forklifts to ensure safe operation

- Accountability for forklift damage/accidents

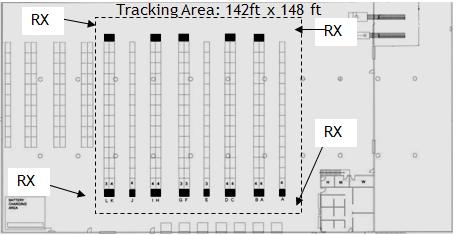

Q-Track has implemented a number of forklift tracking system pilots to assess performance. In one pilot at the JITS Warehouse in Huntsville, AL, we deployed four receivers to cover a 142ft x 148ft (43m x 45m) area including racks loaded with pallets three to four high.

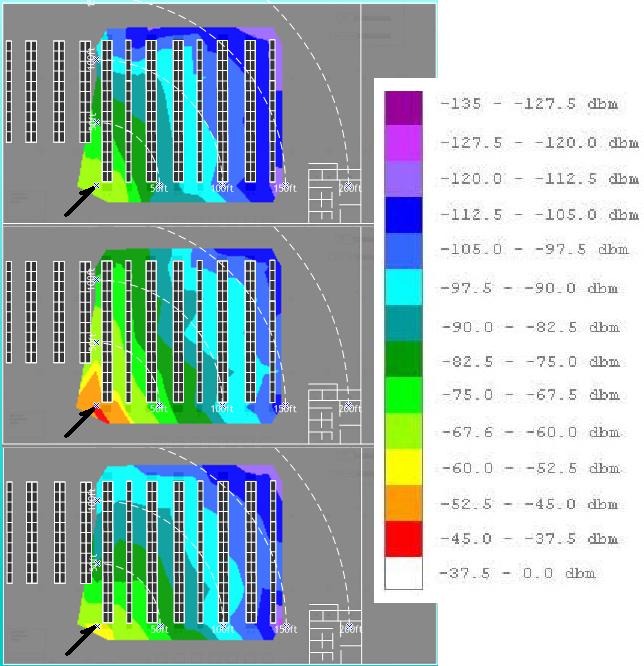

The NFER® RTLS system tracked a forklift to bin-level accuracy (within four feet) throughout the area, despite the complicated non-line-of-sight environment. This performance follows from the low-frequency (~1MHz), long-wavelength (~300m) nature of the signals employed by NFER® RTLS systems. Long-wavelength signals bend and diffract around obstructions like metal racks, enabling excellent coverage, even in cluttered and obstructed settings. The figure below plots the received power throughout the area.

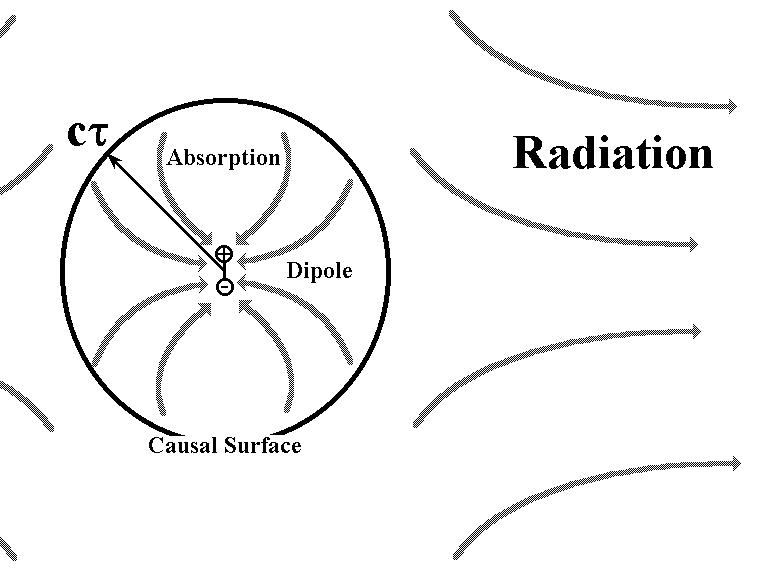

Employing long-wavelength signals has advantages beyond excellent propagation. Operation in the near-field means more parameters are available for precision tracking. Far-field signals have only two possible polarizations. Near-field signals exhibit a third radial or longitudinal polarization. Also, the electric and magnetic fields retain their separate identities in the near-field region providing still more tracking parameters. This target-rich environment enables precise tracking of forklifts in cluttered environments.

The video below shows results from a second pilot within the warehouse.

Q-Track is working with a couple of potential customers to implement NFER® forklift tracking systems, and would welcome the opportunity to deploy additional systems.

2 thoughts on “NFER® RTLS for Forklift Tracking and Supply Chain Management”

What kinds of data are recorded from this system? Can you record how long the asset was in motion, multiple assets at the same time, how long not in motion, history of all paths taken in a given time, for example.

I look forward to your responce. Thanks.

Kindest Regards,

Stephen Henley

Stephen,

Q-Track provides an API (application programming interface) that allows you to take the real time tracking data and analyze it to provide the desired information. That can include how often the forklifts are in motion, not in motion, a spaghetti diagram of the history of the paths taken over time or a playback of the paths taken. This can be done for multiple forklifts with a tracking rate of 8 assets/second.