Armig Kandoian received U.S. Patent 2,368,663 for his invention of the discone antenna in 1945. The basic idea behind a discone antenna is to drive a circular disk against a conical ground. Kandoian was motivated by the problem of trying to mount antennas to aircraft. In alternate embodiments, Kandoian showed rounded and streamlined radomes to reduce air resistance. The discone has been a standard broadband design for many years, particularly in a thin wire implementation.

About twenty years ago, a couple of engineers devised an improvement to the classic design.

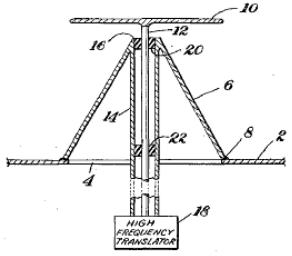

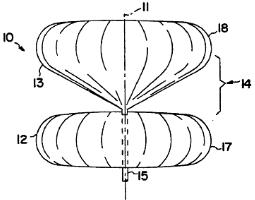

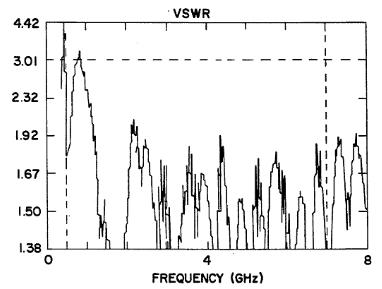

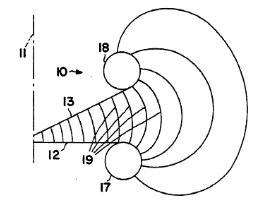

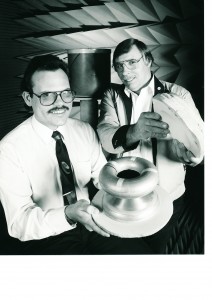

Keith A. Snyder and Gary Peisley received U.S. Patent 5,140,334 in 1991 for their “Compact omnidirectional antenna.” They took Kandoian’s discone, inverted the elements, and rounded the edges. In their design, a rounded conical element is driven against a circular ground plane with rounded edges. The antenna VSWR is 3:1 or better from 500MHz to 7GHz and is 2:1 or better over most of that range.

The idea behind the rolled edge is to create a more gradual transition from the guided wave between the two antenna elements to the free-space wave. The rolled edge helps minimize the reflection that might otherwise occur at the boundary, improves the matching, and extends the bandwidth particularly at the lowest frequencies of operation. Thus the antenna can be made smaller than would be possible without the rolled edge. This same technique has been applied to reduce diffraction from the edges of parabolic and other reflector antennas. Snyder and Peisley achieved this performance in an antenna 9in (23cm) in height and 19in (48cm) in diameter.

I briefly described this antenna in The Art and Science of UWB Antennas (see Fig. 6.4, p. 205). However, I did not fully appreciate that the wizardary of the antenna lies not only in the design itself, but also in the method of construction. Snyder’s and Peisley’s invention also includes a method of forming the antenna elements in metallically coated molds with a fiberglass-resin mix. Keith Snyder explains:

“I was looking for styrofoam to wrap with tin foil when Gary mentioned he could make a swept mold in plaster and then used fiberglass in the mold with metallic paint and a release agent. All in all it was thanks to Gary that we could create the shape needed back then.”